In today’s rapidly evolving infrastructure industry, sustainability has become more than a buzzword; it is a necessity. The RAP Hot Recycling Asphalt Mixing Plant offers an innovative solution to the challenges posed by road construction and maintenance, aligning environmental responsibility with economic benefits. Let’s delve into this game-changing technology and uncover why it is the best choice for modern road projects.

What Is a RAP Hot Recycling Asphalt Mixing Plant?

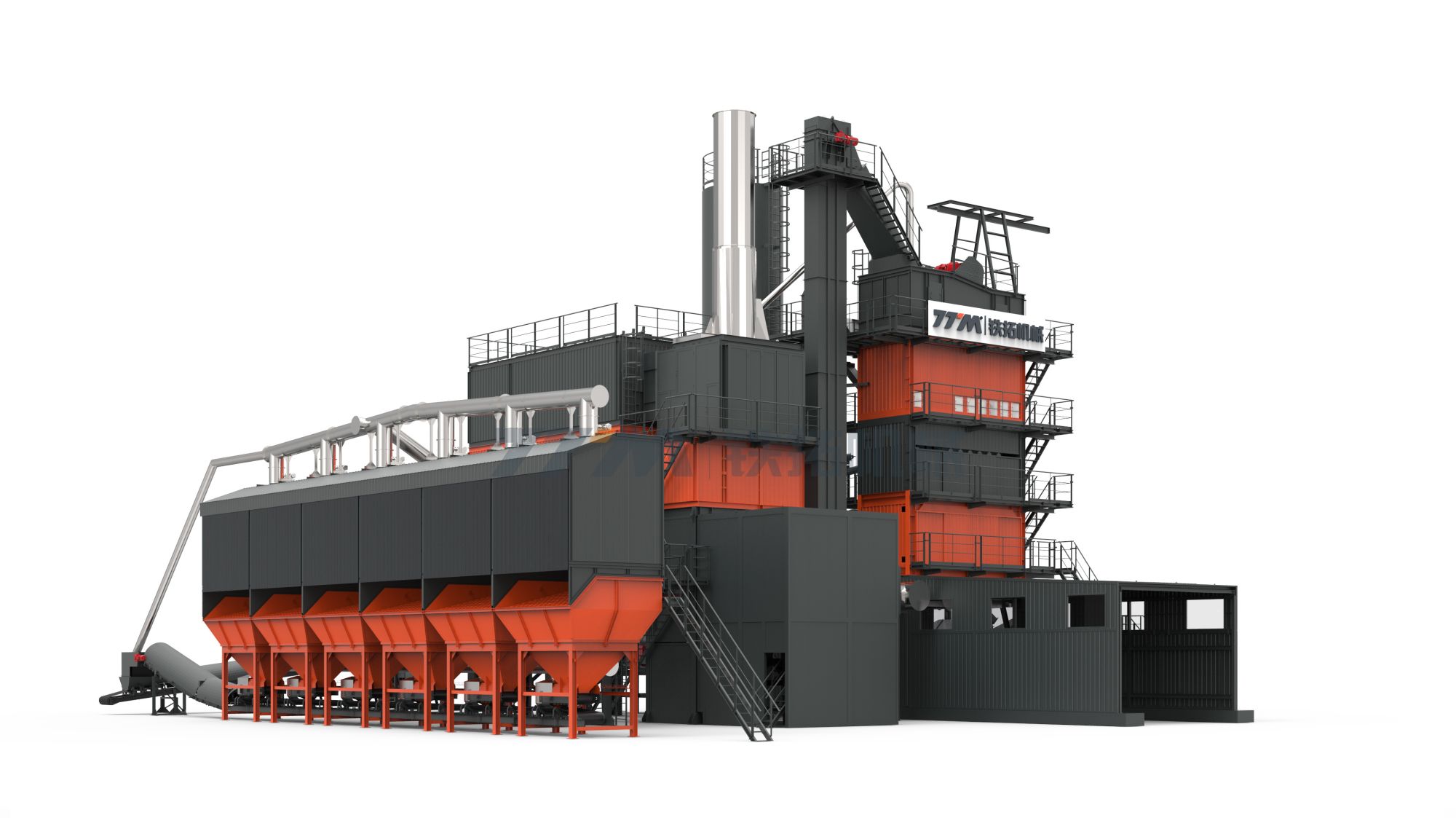

The RAP Hot Recycling Asphalt Mixing Plant is designed to recycle reclaimed asphalt pavement (RAP), transforming it into usable material for paving and maintenance. This eco-friendly solution addresses environmental concerns by reducing waste and minimizing the need for virgin materials, while also delivering significant cost savings.

Its application spans various grades of road projects, from small-scale repairs to large-scale constructions, making it a versatile asset for maintenance and construction companies.

For detailed specifications, visit TTM Asphalt Mixing Plant.

Key Features and Technological Advancements

The RAP Hot Recycling Asphalt Mixing Plant integrates cutting-edge features to ensure efficiency, environmental compliance, and long-term durability.

1. Advanced Furnace Design

The furnace structure is engineered to prevent direct contact between RAP and the burner flame, reducing the risk of overheating and ensuring consistent material quality. With an internal ceramic fiber layer, the furnace offers:

- Lightweight and low heat absorption.

- Enhanced noise reduction.

- Easy maintenance and repair capabilities.

The result is a system that delivers reliable heating while preserving the integrity of the asphalt material.

2. Innovative RAP Drying Drum

This patented design (Patent No. ZL200810189181.1) solves common adhesion problems in RAP drying. Key features include:

- Soft elevating chains to prevent material sticking.

- Hook-shaped lifting paddles for graded heating of coarse and fine materials.

- Gentle heating through a large-diameter drum with low rotation speed, minimizing asphalt aging and ensuring high-quality output.

3. Emission Processing System

The plant addresses environmental concerns through a double-cyclone emission system:

- An internal circulation pipeline controls the air temperature within the RAP drying drum.

- A re-burning system purifies emissions, reducing pollutants and meeting strict environmental standards.

This dual approach ensures compliance with national environmental protection policies, making it a sustainable choice for the future.

4. Pre-Mixing RAP Technology

Pre-mixing extends the interaction between RAP and additives, allowing for:

- Better dispersion and penetration of materials.

- Enhanced bonding and uniformity.

- Reduction of adhesion and air emission issues during processing.

The manual switching device adds operational flexibility, enabling seamless transitions between pre-mixing and direct discharge.

Why Choose RAP Hot Recycling Asphalt Mixing Plants?

- Environmental Benefits: By recycling RAP, the plant significantly reduces waste and conserves natural resources.

- Economic Advantages: Recycling materials lowers production costs and maximizes the value of existing asphalt.

- Versatility: Suitable for a variety of road projects, from minor repairs to major reconstructions.

- Compliance and Innovation: Meets national environmental standards while incorporating cutting-edge technology to ensure high-quality results.

TTM: A Leader in Asphalt Mixing Technology

Established in July 2004, Fujian TieTuo Machinery Co., Ltd. (TTM) is at the forefront of the asphalt mixing industry. With a product portfolio that includes Hot Recycling Facilities of RAP, Cold Recycling Facilities of RAP, and Dry Mortar Mixing facilities, TTM combines innovation, quality, and exceptional service.

Our RAP Hot Recycling Asphalt Mixing Plants exemplify our commitment to sustainable solutions, offering unparalleled efficiency and environmental protection.

The RAP Hot Recycling Asphalt Mixing Plant is more than just equipment; it is a step toward a sustainable future. By combining advanced technology with environmental responsibility, it addresses the needs of modern road construction while ensuring long-term economic benefits.

For more information and to explore our range of innovative solutions, visit TTM Asphalt Mixing Plant.