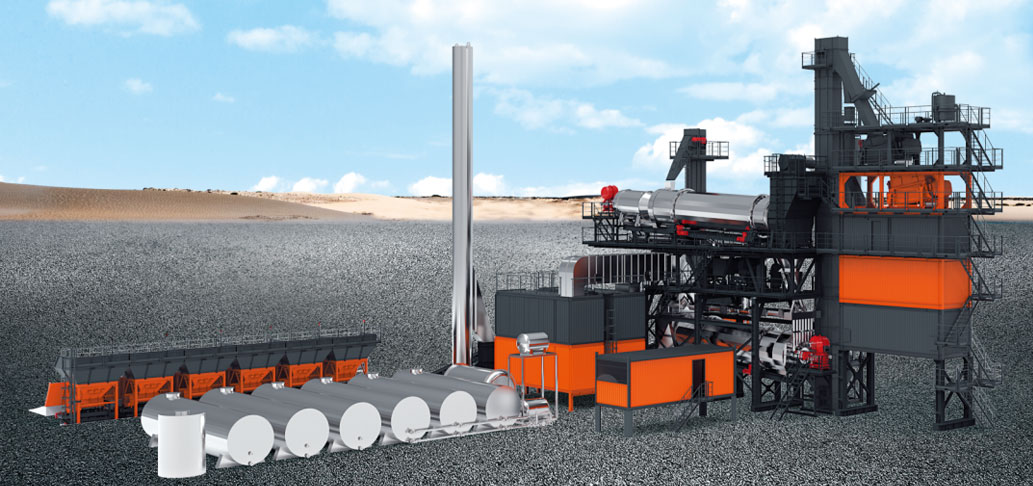

Continuous Asphalt Mixture Mixing Equipment

Energy-saving Advantages

-

Compared to batch asphalt mixture mixing equipment, continuous asphalt mixture mixing equipment eliminates processes such as hot aggregate screening, storage, and weighing.

-

Reduced Heat Loss: The heat dissipation area from the drum outlet to the mixing barrel outlet is reduced by 85%. The drum discharge temperature can be lowered by approximately 10°C.

-

Lower Power Consumption: Aggregate lifting power is reduced by 50%, powder lifting is eliminated, and there is no vibrating screen or electric hoist. Hot material bins and hot aggregate weighing scales are removed, reducing air compressor power by 30%. Overall, the entire machine’s power consumption is saved by about 15%.

-

No Material Overflow: The economic loss for each ton of overflowing hot aggregate is about 25 RMB. For equipment with an annual output of 300,000 tons, the annual loss could reach approximately 500,000 RMB.

Environmental Advantages

-

Less Dust Emission: Avoids dust problems at soft connections in batch equipment; no dust caused by material overflow.

-

Reduced Exhaust Emissions: Less heat dissipation leads to a lower drum discharge temperature. Burner fuel consumption decreases, resulting in reduced exhaust emissions.

Mixing Quality Advantages

-

Controllable Aggregate Gradation: Source control avoids gradation errors caused by secondary vibrating screening.

-

Stable Temperature Control: Reduced heat loss and cooling processes. The temperature difference between drum discharge and mixing is minimal, allowing better temperature control when mixing asphalt and hot aggregates.

-

Asphalt Aging Control: During production, there is no air pressure fluctuation, and the oxygen content in the mixing environment is low, minimizing asphalt oxidation during mixing.

Key Technical Solutions

Aggregate Weighing

-

TTM patented technology enables precise continuous weighing of aggregate flow.

-

The control system automatically adjusts asphalt flow based on aggregate flow and preset oil-to-stone ratio parameters, achieving precise oil-to-stone ratio control.

-

Automatic scale calibration.

-

Tested dynamic weighing accuracy is within ±1.5%.

Asphalt Weighing

TTM patented technology allows online calibration of asphalt flow during normal equipment operation. This method is simple, efficient, and does not interrupt equipment operation.

Powder Weighing

TTM patented technology enables online calibration of the metering screw during normal operation. The process is easy, efficient, and does not affect equipment operation.

Mixing Uniformity Control

-

Two dual-horizontal-shaft forced mixers operate in a stepped mixing sequence for extended mixing time.

-

Adjustable discharge gate opening.

-

Specially arranged mixing blade combinations can be quickly adjusted according to the characteristics of the actual mixture being produced.