RAP Roller Crushing and Screening Equipment

The RPS100 RAP roller crushing and screening equipment is a brand new specialized crushing and screening product launched by Fujian Tietuo Machinery Co., Ltd. based on its years of design experience in asphalt plant hot recycling equipment, combined with the special characteristics of domestic RAP material acquisition methods.

Roller Crushing and Screening Technology Advantages:

- Single roller crusher uses protective plates made of wear-resistant materials to protect standard cutter heads, with strong crushing capability, good wear resistance, convenient replacement, and extended equipment service life;

- Low-speed main shaft can effectively reduce dust emissions;

- Floating double roller crushing effectively prevents instantaneous equipment failure caused by large RAP materials;

- Staggered arrangement of wear-resistant tooth plates effectively crushes RAP materials without material adhesion;

- High-frequency vibrating screen combined with anti-clogging hole screen technology effectively solves fine aggregate adhesion to screens.

Roller Crushing and Screening Working Principle

The crushing and screening system screens mechanically excavated or milled RAP materials according to specifications, and sends oversized materials to secondary crusher for crushing and re-screening.

For oversized RAP materials obtained through mechanical excavation, they are crushed by the primary crusher with combined action of spiral main shaft and hydraulic pressure device, then stored in cold material bins;

For milled RAP materials, they can be directly fed from cold material bins into vibrating screens for screening. The screened materials are divided into 2 or more types for storage. Oversized RAP materials undergo secondary crushing through double roller system, transported by belt to vibrating screen for screening until crushed to qualified RAP materials.

Primary Roller Crusher

- Spiral crushing roller and hydraulic pressure device work simultaneously to effectively crush large RAP materials;

- Standard crushing cutter heads with good wear resistance and easy replacement;

- Spring tensioning device behind crushing shaft prevents instantaneous equipment failure caused by oversized RAP materials.

Cold Material Bin

- Split-type cold material bin ensures effective volume and convenient transportation;

- Grid on top of bin with maintenance-free vibrating motor drive removes oversized materials and prevents material blockage;

- Special bin structure effectively prevents material arching.

Vibrating Screen

- Linear screen driven by dual vibrating motors with maintenance-free design. Screen mesh is tensioned front and back for convenient maintenance and replacement;

- High-frequency vibrating screen combined with anti-clogging hole screen technology effectively solves fine aggregate adhesion.

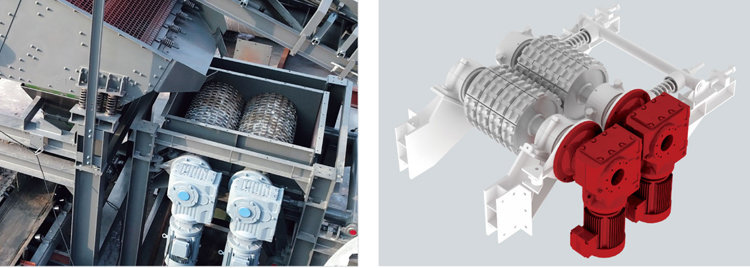

Double Roller Secondary Crusher

- Double roller secondary crusher with floating crushing rollers can adjust discharge particle size and effectively protect against instantaneous equipment failure caused by oversized RAP materials;

- Staggered arrangement of high wear-resistant tooth plates can effectively crush oversized RAP materials.

Model: RPS100

Total Power: 121kW

Rated Production Capacity: 100t/h

Maximum Feed Size: 800mm