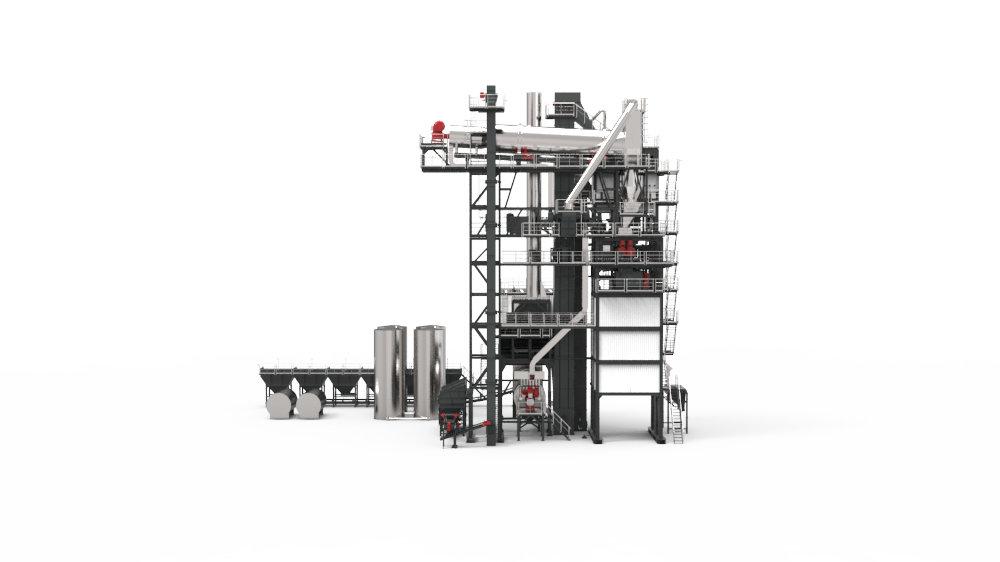

TS Series (Integrated)

The GLBE Series Environmental Asphalt Mixing Equipment (With Bottom-Mounted Storage Silo) features an integrated design with optimized functional structure to meet environmental protection requirements. The main tower offers two enclosure options: modular sealed structure and fully enclosed structure, providing customers with multiple choices.

Semi-Enclosed Structure:

The equipment main tower adopts modular sealed structure design, with external sealing packages for dust points on each level, effectively preventing dust dispersion outside the equipment. The main tower external package features unique sliding door design, making equipment operation more user-friendly. The entire machine has optimized dust prevention measures at cold aggregate bins, belt discharge points, roadways and other locations, ensuring full compliance with environmental requirements.

Fully Enclosed Structure:

The equipment main tower adopts unique and innovative exterior structure design that is simple, elegant, and easy to assemble. The main tower’s external sealed design and dust collection pipelines on each level ensure dust and smoke have no escape route, effectively improving the overall environmental performance of the equipment.

Environmental Highlights:

Energy Conservation Measures:

- High-temperature components exposed to air are equipped with additional insulation layers to reduce heat loss;

- Electric heating system for asphalt storage system heating and insulation, replacing traditional thermal oil boiler heating methods;

- Higher energy-efficiency grade motors driving reducers to improve equipment power energy conservation;

- Foam asphalt warm mix function module available, making production process more energy-efficient and environmentally friendly.

Dust Prevention and Deodorization Measures:

- Self-developed gas burners to meet customer requirements for clean fuel usage;

- Dust and smoke from finished material discharge ports are sent into burner flames for secondary combustion;

- Asphalt tanks and heavy oil tank exhaust outlets are equipped with ventilation condensers to reduce asphalt smoke overflow, or photocatalytic oxidation and activated carbon adsorption devices for centralized asphalt smoke treatment;

- Cold aggregate system configured with dedicated pulse bag dust collector to solve dust problems during loader feeding and belt conveyor transport;

- Recovery powder humidification mixing device installed at powder silo discharge outlet to reduce dust during recovery powder discharge;

- Foam asphalt warm mix function module available to reduce asphalt smoke during production process;

- Raw material storage areas can be equipped with water mist spraying devices to effectively control site dust.

Noise Reduction Measures:

- Sound insulation covers added around induced draft fans, with shock-absorbing cushion pads at fan base and silencing equipment at fan chimney outlets to reduce noise pollution;

- (High-efficiency) silencers and sound insulation covers configured for burners to reduce noise;

- Noise points such as main tower elevators and vibrating screens adopt aluminum silicate thermal insulation cotton and color steel plate external packaging design for energy conservation and noise reduction effects.

| Specification | TS1006 | TS1510 | TS2010 | TS2015 | TS3015 | TS3020 | TS4020 | TS4030 | TS5030 |

|---|---|---|---|---|---|---|---|---|---|

| Standard Production Capacity (t/h) | 80 | 120 | 160 | 160 | 240 | 240 | 320 | 320 | 400 |

| Standard Mixing Capacity (t/h) | 48 | 80 | 80 | 120 | 120 | 160 | 160 | 240 | 240 |

| Reclaimed Material Proportion (%) | 40% | 50% | 50% | 37.5% | 50% | 50% | 40% | 60% | 60% |

| Mixing Power (kW) | 100~120 | 140~160 | 160~240 | 200~240 | 280~320 | 280~320 | 360~400 | 420~480 | 420~480 |

| Cold Aggregate Bin Quantity (Main Part) | 4 | 4 | 5 | 5 | 6 | 6 | 6 | 6 | 6 |

| Bin Capacity (m³) | 8 | 8 | 15 | 15 | 15 | 15 | 15 | 15 | 18 |

| Belt Conveyor Model | GT100 | GT100 | GT160 | GT160 | GT240 | GT240 | GT320 | GT320 | GT400 |

| Belt Speed (m/s) | 1.9 | 1.9 | 2.25 | 2.25 | 2.5 | 2.5 | 2.7 | 2.7 | 3 |

| Inclination Angle (°) | 9 | 9 | 10 | 10 | 10 | 10 | 12 | 12 | 12 |

| Burner Fuel Type | Diesel / Heavy Oil / Pulverized Coal / Natural Gas / Liquefied Gas (Optional Dual Fuel) | ||||||||

| Fuel Consumption (kg/t) | 18 | 22 | 29 | 29 | 39 | 39 | 55 | 55 | 88 |

| Baghouse Filtering Area (m²) | 510 | 650 | 920 | 920 | 1200 | 1200 | 1600 | 1840 | 1840 |

| Number of Filter Bags | 4 | 4 | 5 | 5 | 6 | 6 | 6 | 6 | 6 |

| Baghouse Capacity (m³) | 12 | 25 | 28 | 28 | 50 | 50 | 80 | 80 | 80 |

| Exhaust Fan Power (kW) | 1500 | 2000 | 3000 | 3000 | 4000 | 4000 | 5000 | 7500 | 7500 |

| Finished Bin Quantity | Double Bin / Three Bin (Optional) | Single Bin / Double Bin / Three Bin / Four Bin (Optional) | Four Bin or more (Optional) | ||||||

| Finished Bin Capacity (t) | 100 | 200/300 | 200/300/400 | 200/300/400 | 200/300/400 | 200/300/400 | |||

| Weighing Capacity per Batch (kg) | 100/200 | 100/200 | 200/300/400 | 200/300/400 | 200/300/400 | 200/300/400 | |||

| RAP Dryer Model | RGT64 | RGT80 | RGT80 | RGT120 | RGT120 | RGT120 | RGT160 | RGT160 | RGT240 |

| Diameter (m) | 1.8 | 2.25 | 2.25 | 2.5 | 2.5 | 2.5 | 2.7 | 2.7 | 3 |

| Length (m) | 8 | 9 | 9 | 10 | 10 | 10 | 12 | 12 | 12 |

| Fuel Type | Diesel / Heavy Oil / Pulverized Coal / Natural Gas / Liquefied Gas | ||||||||

| Fuel Consumption (kg/t) | 5.9 | 9.8 | 9.8 | 14.8 | 14.8 | 14.8 | 19.7 | 19.7 | 29.6 |

| Exhaust Fan Diameter (m) | Φ1.6*3.8 | Φ2*4.2 | Φ2*4.2 | Φ2*4.2 | Φ2*4.2 | Φ2*4.2 | Φ2.5*11 | Φ2.5*11 | Φ2.5*11 |

| Number of Bags | 8 | 8 | 8 | 10 | 10 | 10 | 18 | 18 | 18 |

| RAP Bin Capacity (kg) | 1000 | 1000 | 2000 | 2000 | 2000 | 2000 | 3000 | 3000 | 3000 |

| Drying Drum Drive Power (kW) | 90 | 110 | 160 | 185 | 185 | 200 | 200 | 200 | 430 |