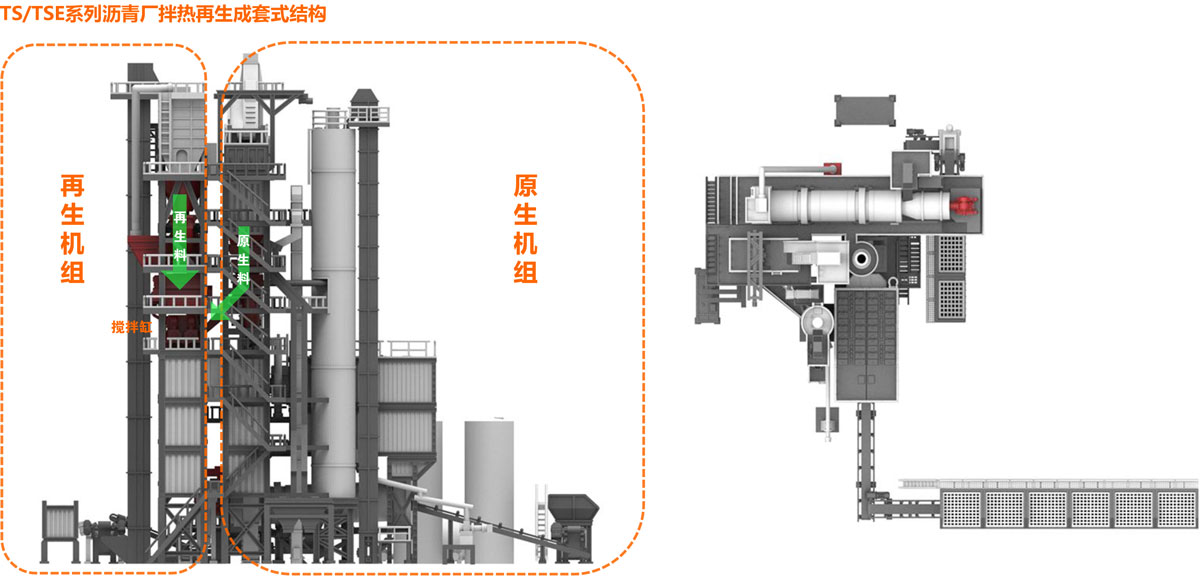

TSE Environmental-Friendly Plant Hot Recycling Complete Equipment

The TS series is an integrated asphalt plant hot recycling equipment independently developed by Tietuo Machinery, which recycles and reuses waste asphalt mixture, returning it to the road surface. This not only solves environmental pollution problems but also creates good economic benefits for customers, achieving green transportation.

The equipment mixing system is positioned below the recycling weighing scale, completely avoiding material adhesion and blockage problems caused by using recycling chutes and belt conveyors (virgin materials slide into the mixing host through chutes). The integrated design of recycling and virgin materials optimizes the configuration scheme of the dust removal system and mixing host, which can greatly improve the production efficiency of the entire equipment. The complete machine is also equipped with a patented pre-mixing switching device that can be selected and switched at any time according to production needs.

Environmental Highlights:

Energy-saving Measures:

- High-temperature components exposed to air are all equipped with insulation layers on the outer surface to reduce heat loss;

- Electric heating is used for the asphalt storage system heating and insulation, replacing the traditional thermal oil boiler heating method;

- Higher energy-efficient grade electric motors are used to drive reducers, improving the equipment’s electrical energy-saving level;

- Foam asphalt warm mix functional module is provided, making the production process more energy-efficient and environmentally friendly.

Dust Prevention and Deodorization Measures:

- Self-developed gas burner to meet customers’ requirements for clean fuel use;

- Finished material discharge port smoke and dust are sent into burner flame for secondary combustion;

- Asphalt tank and heavy oil tank exhaust ports are equipped with ventilation condensers to reduce asphalt smoke overflow, or use photo-oxygen catalysis, activated carbon adsorption and other devices for centralized asphalt smoke treatment;

- Cold material system is equipped with dedicated pulse bag dust collector to solve dust problems generated during loader feeding and belt conveyor transportation;

- Install recovered powder humidification mixing device at powder tank discharge outlet to reduce dust during recovered powder discharge;

- Provide foam asphalt warm mix functional module, reducing asphalt smoke during the production process;

- Raw material sites can be equipped with water mist spraying devices to effectively control dust in the site.

Noise Reduction Measures:

- Add sound insulation cover around induced draft fan, while adding shock-proof cushion pads at the bottom of induced draft fan. The induced draft fan chimney outlet is equipped with silencing equipment to reduce noise pollution;

- Configure (high-efficiency) silencers and sound insulation covers for burners to reduce noise;

- For noise points such as main building hoists and vibrating screens, adopt aluminum silicate insulation cotton insulation and color steel plate external packaging design for energy-saving and noise reduction effects.

| TSE1006 | TSE1510 | TSE2010 | TSE2015 | TSE3015 | TSE3020 | TSE4020 | |

|---|---|---|---|---|---|---|---|

| Standard production capacity of virgin material (/h) | 80 | 120 | 160 | 160 | 160 | 240 | 320 |

| Standard production capacity of recycled material (/h) | 48 | 80 | 80 | 120 | 120 | 160 | 160 |

| Minimum energy consumption of equipment performance (%) | 40% | 50% | 33% | 50% | 37.50% | 50% | 40% |

| Production capacity when adding recycled material in standard conditions (/h) | 100~120 | 140~160 | 200~240 | 200~240 | 280~320 | 280~320 | 360~400 |

| Virgin Material Section | |||||||

| Cold material supply system (virgin section) | Number of hoppers can be configured according to customer requirements (virgin section) | ||||||

| Number of dosing hoppers | 4 | 4 | 5 | 5 | 6 | 6 | 6 |

| Single dosing hopper volume (m³) | 8 | 8 | 8 | 8 | 15 | 15 | 15 |

| Drying drum model | GT100 | GT120 | GT160 | GT160 | GT240 | GT240 | GT320 |

| Diameter (m) | 1.75 | 1.95 | 2.25 | 2.25 | 2.5 | 2.5 | 2.7 |

| Length (m) | 7 | 8 | 9 | 9 | 10 | 10 | 10 |

| Burner (drying drum) | Fuel/diesel heavy oil dual-use/coal powder/natural gas/oil-gas dual-use (can be selected according to customer requirements) | ||||||

| Combustion power (MW) | 9.8 | 14.8 | 19.7 | 19.7 | 29.6 | 29.6 | 39.4 |

| Dust removal system | Gravity + bag filter | ||||||

| Bag filter area (m²) | 510 | 650 | 920 | 920 | 1200 | 1200 | 1500 |

| Number of hot bins | 4 | 5 | 6 | ||||

| Hot bin volume (m³) | 12 | 25 | 28 | ||||

| Exhaust capacity (kg) | 1500 | 2000 | 3000 | 4000 | 5000 | ||

| Exhaust transmission form | Dual reduction motor drive (gear synchronization) | ||||||

| Finished product silo | Bottom-mounted/side-mounted | ||||||

| Bottom-mounted finished product silo volume (ton) | 100 | 200/300 | 200/300/400 | ||||

| Side-mounted finished product silo volume (ton) | 100/200 | 200/300/400 | |||||

| Recycled Material Section | |||||||

| Drying drum | |||||||

| Drying drum model | RGT64 | RGT80 | RGR80 | RGT120 | RGT120 | RGT160 | RGT160 |

| Diameter (m) | 1.8 | 2.25 | 2.5 | ||||

| Length (m) | 8 | 10 | 12 | ||||

| Burner (drying drum) | Fuel/diesel heavy oil dual-use/natural gas/oil-gas dual-use | ||||||

| Combustion power (MW) | 5.9 | 9.8 | 14.8 | 19.7 | |||

| Combustion capacity/length-diameter | 91.6*3.8 | 91.8*4.2 | 92*4.2 | ||||

| Recycled storage silo capacity (ton) | 8 | 10 | |||||

| Recycled mixer | Can be selected according to user choice | ||||||

| Recycled mixer capacity (kg) | 600 | 1000 | 1500 | 2000 | |||

| Waste gas treatment method | Enter main storage for secondary combustion | ||||||

| Recycled mixer mixing method | Channel and fast belt (optional) | ||||||

| Maximum motor power (Kw) | 90 | 110 | 160 | 160 | 185 | 185 | 200 |