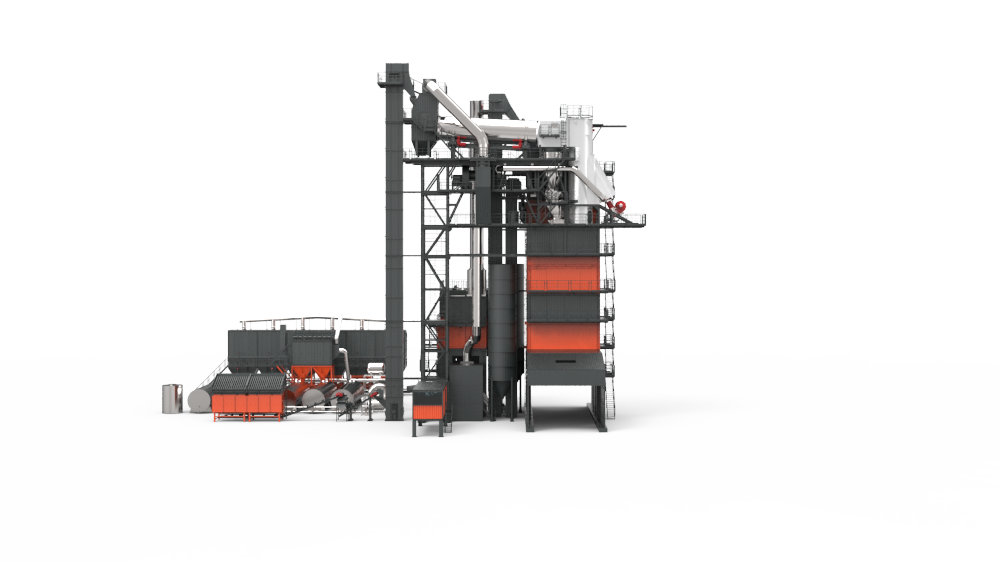

TSEC Series Environmental Protection Complete Equipment

1. 3000 Type Counter-flow Asphalt Plant Hot Recycling

Adopts counter-flow heating method with high thermal efficiency and low fuel consumption. The drum uses large diameter, low rotation speed, and small inclination angle structure, allowing recycled materials to be heated slowly and gently in the drum, ensuring discharge temperature while reducing asphalt aging degree. The drum has built-in special flexible lifting blades, greatly reducing adhesion on the drum wall and blades, enhancing the drum’s self-cleaning capability.

2. Vertical Hot Air Furnace

The hot air furnace adopts lightweight vertical structure design with built-in ceramic fiber layer. It has light bulk density, extremely low heat absorption, lower noise, and is replaceable and repairable for convenient maintenance. The furnace structure design is compact, reducing equipment length and footprint for more flexible supporting use. During operation, the heat exchange space is more sufficient. Introduction of low-temperature tail gas and gentle mixing with burner hot smoke can effectively control the heating medium temperature.

3. RAP and Regenerating Agent Pre-mixing System

The pre-mixing system is designed with manual switching device, allowing customers to freely switch between pre-mixing cylinder or direct chute according to usage requirements, while avoiding equipment structural adhesion, smoking and other problems.

4. 7500 Type Four-drive Ultra-large Capacity Mixing Cylinder

The mixing cylinder is placed on the recycling main unit, adopting 7500 type mixing cylinder equipped with 4 synchronized reducer drives for strong power. The double mixing arm layout and spiral blade arrangement make mixing efficiency higher. The discharge door adopts rotary structure design for fast unloading speed.

TSEC Series Environmental Performance and Measures

The TSEC series complete machine main building adopts modular sealed structure design, externally sealing dust points at each level, effectively preventing dust diffusion outside the equipment. The main building external packaging adopts unique sliding door design, which is not only dustproof but also more user-friendly during operation. The complete machine optimizes dust prevention measures at cold material bins, belt discharge outlets, roadways and other locations.

Dust Prevention, Deodorization, and Noise Reduction Measures

- Self-developed gas burner to meet customers’ requirements for clean fuel use;

- Finished material discharge port smoke and dust are sent into burner flame for secondary combustion;

- Asphalt tank and heavy oil tank exhaust ports are equipped with ventilation condensers to reduce asphalt smoke overflow, or use photo-oxygen catalysis, activated carbon adsorption and other devices for centralized asphalt smoke treatment;

- Cold material system is equipped with dedicated pulse bag dust collector to solve dust problems generated during loader feeding and belt conveyor transportation;

- Install recovered powder humidification mixing device at powder tank discharge outlet to reduce dust during recovered powder discharge;

- Provide foam asphalt warm mix functional module, reducing asphalt smoke during production process;

- Raw material sites can be equipped with water mist spraying devices to effectively control dust in the site;

- Add sound insulation cover around induced draft fan, while adding shock-proof cushion pads at the bottom of induced draft fan. The induced draft fan chimney outlet is equipped with silencing equipment to achieve noise reduction effect;

- Configure (high-efficiency) silencers and sound insulation covers for burners to reduce noise;

- For noise points such as main building hoists and vibrating screens, adopt aluminum silicate insulation cotton insulation and color steel plate external packaging design for energy-saving and noise reduction effects.

| Model/Specifications | TSEC1510 | TSEC2015 | TSEC3015 | TSEC3020 | TSEC4020 | TSEC4030 | TSEC5030 | |

|---|---|---|---|---|---|---|---|---|

| Virgin Material Production Capacity (t/h) |

120 | 160 | 240 | 240 | 320 | 320 | 400 | |

| Recycled Material Production Capacity (t/h) |

80 | 120 | 120 | 160 | 160 | 240 | 240 | |

| Optimal Mixing Ratio (%) | 50% | 50% | 37.5% | 50% | 40% | 60% | 50% | |

| Overall Machine Production Capacity (t/h) |

140~160 | 200~240 | 280~320 | 280~320 | 360~400 | 440~480 | 480~520 | |

| Virgin Drying Drum | GT120 | GT160 | GT240 | GT320 | GT400 | |||

| Diameter (m) | 1.95 | 2.25 | 2.5 | 2.7 | 3 | |||

| Length (m) | 8 | 9 | 10 | 10 | 12 | 12 | ||

| Burner Power (MW) | 11.8 | 19.7 | 21.3 | 27.8 | 35.5 | |||

| Bag Filter Area (m²) |

650 | 920 | 1200 | 1500 | 1940 | 1940 | ||

| Mixing Cylinder Capacity (kg) | 2000 | 3000 | 4000 | 5500 | 7500 | |||

| Mixing Cylinder Drive System | Double Reduction Motor Drive | Quad Reduction Motor Drive | ||||||

| Recycling Drying Drum | RGT80 | RGT120 | RGT160 | RGTC240 | ||||

| Diameter (m) | 2.25 | 2.5 | ||||||

| Length (m) | 8 | 10 | 12 | |||||

| Burner Power (MW) | 9.8 | 14.8 | 19.7 | 21.3 | ||||

| Burner Diameter × Length | ø1.8×4.2 | ø2×4.2 | ø2.5×11 | |||||

| Recycling Temporary Storage Capacity | 9 | 12 | ||||||

| Recycling Mixing Silo Capacity (kg) |

1000 | 1500 | 2000 | 3000 | ||||

| Waste Gas Treatment Method | Secondary Combustion in Virgin Drum | |||||||

| Recycled Material Feeding Method to Mixing Silo | Direct Type (Mixing silo located below recycling main building, no chute) | |||||||